- Description

- Specifications

- Documents

Manufacturing Note:

Kester is currently experiencing a temporary supply disruption affecting several extruded bar solder part numbers due to equipment failure at the manufacturing facility.

To ensure continuity of supply, Kester is offering the same alloys in a cast bar format. Cast bars meet the same alloy specifications, are produced from the same master pots, and provide the same performance characteristics as extruded bars. The only differences are in the forming process and minor variances in bar shape—not in alloy composition or reliability.

The chart below lists the affected extruded bar part numbers and their corresponding cast bar replacements:

| Extruded Bar # | Cast Bar # | Alloy | Lead Content |

| 44-9574-0050 | CB44-9574-0050 | K100LD | Lead-Free |

| N/A | CFB47-9574-0050 | K100LD | Lead-Free |

| 44-7317-0000 | CB44-7317-0000 | Sn10Pb88Ag2 | Leaded |

| 44-0595-0000 | CB44-0595-0000 | Sn5Pb95 | Leaded |

| 44-6040-0050 | CB44-6040-0050 | Sn60/Pb40 | Leaded |

| 44-7150-0000 | Cast Bar Unavailable | Sn62Pb36Ag2 | Leaded |

| 44-6337-0030 | CB44-6337-0030 | Sn63/Pb37 | Leaded |

| 44-6337-0050 | CB44-6337-0050 | Sn63/Pb37 | Leaded |

| 47-6337-0050 | CFB47-6337-0050 | Sn63/Pb37 | Leaded |

| 44-7070-0000 | CB44-7070-0000 | Sn95Ag5 | Lead-Free |

| 44-7080-0000 | CB44-7080-0000 | Sn95Sb5 | Lead-Free |

| 44-7050-0000 | CB44-7050-0000 | Sn96.3Ag3.7 | Lead-Free |

| 44-7040-0000 | CB44-7040-0000 | Sn96.5Ag3.5 | Lead-Free |

| 44-7068-0000 | CB44-7068-0000 | Sn96.5Ag3Cu0.5 | Lead-Free |

| 47-7068-0000 | CFB47-7068-0000 | Sn96.5Ag3Cu0.5 | Lead-Free |

| 44-7000-0000 | CB44-7000-0000 | Sn99 | Lead-Free |

| 44-7012-0000 | CB44-7012-0000 | Sn99.3Cu0.7 | Lead-Free |

| 44-7033-0000 | CB44-7033-0000 | Sn97.0Ag3.0 | Lead-Free |

Kester Ultrapure Tin-Lead (SnPb) Solder Bar

Kester Ultrapure solder bars are engineered for high-reliability electronic soldering, especially in surface mount assembly. Each batch is produced under controlled conditions to minimize oxides and eliminate metallic and non-metallic impurities. This results in:

- Excellent flow characteristics

- Low surface tension

- Consistent, dependable performance

Ultrapure solder conforms to IPC/J-STD-006C and meets the highest industry quality standards. When sourced through authorized distributors, purity is certified for each lot.

Storage & Handling

- Store in a dry, non-corrosive environment between 10°C and 40°C (50°F–104°F).

- Surface darkening over time is normal and does not affect performance.

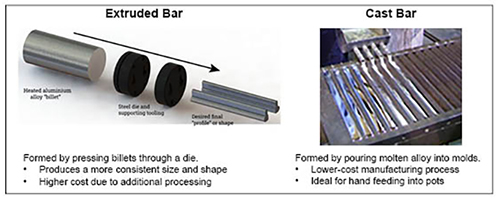

Extruded Bar vs. Cast Bar Processes

Wave and selective solder “make-up bar” is available in several shapes: cast, extruded, anode, ingot, etc. Regardless of format, the purpose is the same—to replenish material removed from the solder pot during use. The alloy itself is identical across all bar types.

Is there any difference in alloy performance?

No. Both extruded and cast bars are made from the same alloy, from the same master pot, and meet the same technical specifications.

Is the shape different?

Yes. Extruded bars are more dimensionally consistent because they are formed through a die, whereas cast bars may show minor shape variations. This difference matters mainly for equipment that uses auto-feeders requiring precise bar dimensions.

Potential Limitation for Lead-Free Cast bar:

Some Electrovert wave soldering machines have a lead-free bar solder option that requires the use of a triangular shaped bar. Our triangular shaped extruded bar fits this equipment. This design is to prevent tin-lead solder from being added into a wave solder machine running lead-free.

This option is only on some Electrovert machines, and we have no knowledge of any other manufacturers with this requirement.

If you plan to convert a customer from extruded bar to cast bar it is advised to inquire if the equipment they use has any limitations on the dimensions of the solder bar.